Fluted metal panels are gaining popularity in modern architecture and design, known for their distinctive ridged patterns that add both aesthetic appeal and functional benefits. These panels not only improve visual interest but also improve structural integrity and energy efficiency. This article explores the characteristics of fluted metal panel and highlights their common applications in residential and commercial settings, showcasing why they’re a smart choice for builders and designers alike.

What Are Fluted Metal Panels?

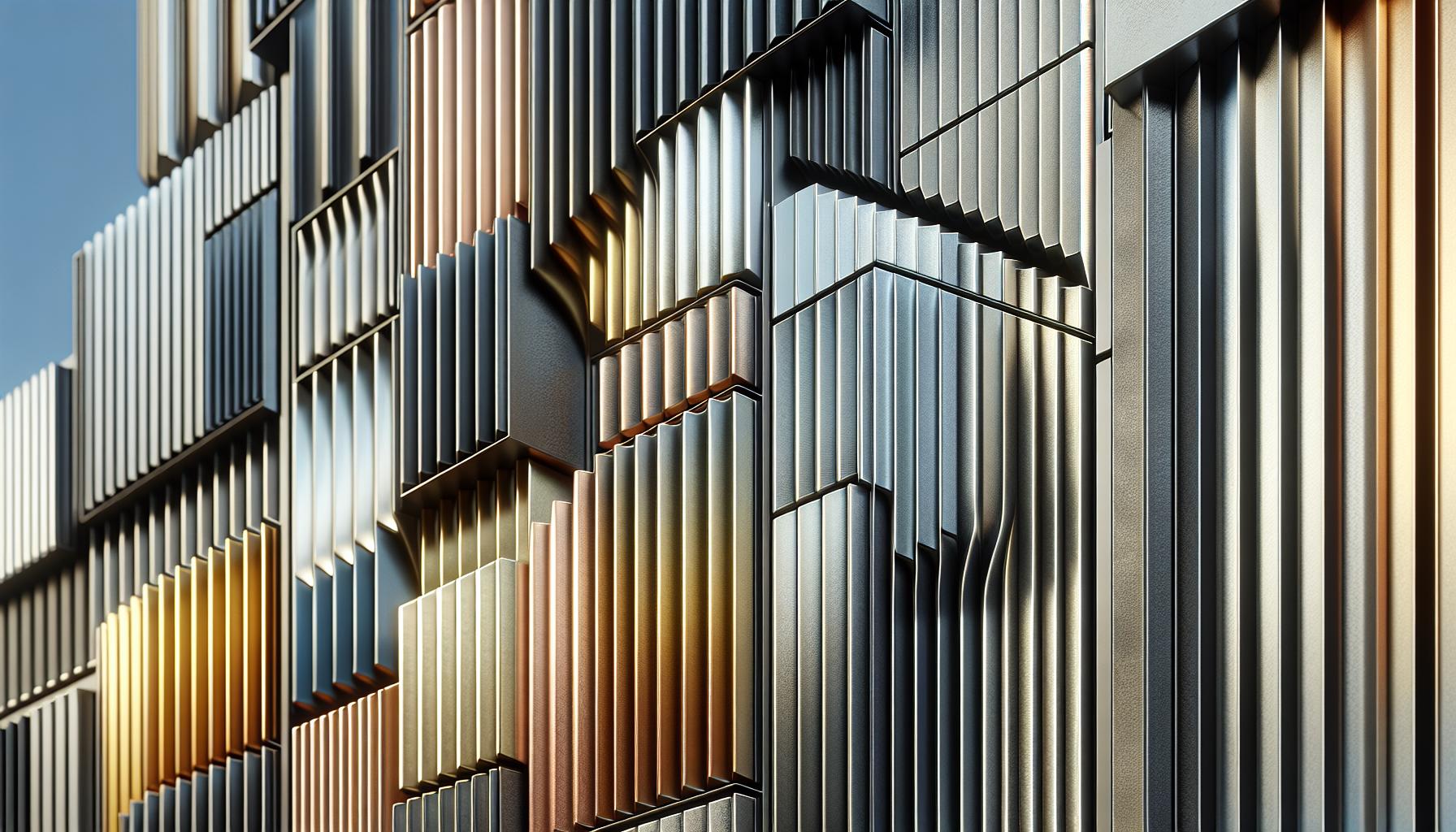

Fluted metal panels feature distinct ridges or grooves that run vertically or horizontally along their surface. This design enhances their visual appeal and adds structural strength, making them a popular choice in architectural applications.

Definition and Features

Fluted metal panels consist of thin sheets of metal formed to create a patterned texture. The fluting process gives the panels rigidity, increasing their resistance to bending and deformation. These panels often come in materials such as aluminum, steel, or stainless steel, offering durability and corrosion resistance. The ridged surface reflects light in unique ways, enhancing shadows and depth, while also allowing for better ventilation when used in exterior applications.

- Vertical Fluted Panels: These panels feature vertically aligned grooves, creating a tall, slim appearance that enhances the sense of height in buildings.

- Horizontal Fluted Panels: With horizontal grooves, these panels lend a more contemporary feel, often used to create a sleek look on larger surfaces.

- Pre-painted Fluted Panels: These panels come with factory-applied finishes, providing consistent color and texture while protecting against rust and fading.

- Perforated Fluted Panels: Featuring holes within the flutes, these panels allow for increased airflow and are often utilized in applications requiring sound dampening or visible light control.

Benefits of Fluted Metal Panels

Fluted metal panels offer several advantages that make them a favored choice in architecture and design. Their unique properties improve both aesthetic and practical aspects of buildings.

Aesthetic Appeal

Fluted metal panels provide a distinct visual interest. The ridges create dynamic light and shadow effects, adding depth to surfaces. This design feature allows for creativity in various applications, from facades to interior walls. The variety of finishes and colors available also ensures compatibility with different architectural styles.

Durability and Maintenance

Fluted metal panels exhibit exceptional durability. Constructed from robust materials, they resist dents, scratches, and environmental wear. Their surface treatments improve corrosion resistance, making these panels suitable for diverse climates. Maintenance requirements remain minimal, often consisting of simple cleanings. This durability reduces the need for frequent replacements, contributing to long-term cost savings.

Common Applications of Fluted Metal Panels

Fluted metal panels see extensive use in multiple industries due to their unique properties and aesthetic appeal.

Architectural Uses

Fluted metal panels commonly appear in building facades, providing both ornamental and protective features. They improve exterior surfaces with their dynamic patterns and textures. Architects utilize them for projects ranging from commercial buildings to residential homes. Their ability to reflect light adds depth to architectural designs. These panels also promote energy efficiency through thermal insulation and can improve airflow when designed with perforations.

Industrial Uses

Fluted metal panels serve critical roles in industrial environments. They frequently protect equipment and machinery by resisting corrosion and impacts. The panels’ durability makes them ideal for factory cladding, storage facilities, and warehouses. They also provide a hygienic surface, suitable for food processing or pharmaceutical industries where cleanliness is essential.

Interior Design

In interior spaces, fluted metal panels add sophistication and interest to design elements. Designers incorporate them in walls, ceilings, and accent pieces, creating visual contrast with smooth surfaces. Their variety of finishes allows integration into diverse design themes, from modern to traditional. The panels can also serve acoustic purposes, helping reduce noise levels in high-traffic areas.

Installation Considerations

When installing fluted metal panels, several key factors impact performance and longevity. Following these considerations ensures effective application and optimal results.

Material Selection

Choosing the right material provides significant advantages. Fluted metal panels can be made from aluminum, steel, or composite materials. Aluminum offers lightweight and corrosion-resistant properties, ideal for exterior applications. Steel, while heavier, provides enhanced strength and durability for structural components. Composite materials combine benefits from metals and can offer improved insulation while maintaining a low weight. It’s vital to select materials that match the environmental conditions and intended use to maximize performance.

Structural Requirements

Adhering to specific structural requirements is essential for successful installation. Fluted metal panels must be properly supported to prevent warping or damage over time. Installers should assess the building’s framework to ensure it can handle the weight and load of the panels. Professionals typically recommend maintaining adequate spacing and using appropriate fasteners to secure panels in place. Additionally, consideration of expansion and contraction due to temperature variations prevents stress on the panels, promoting their longevity and structural integrity.

Conclusion

Fluted metal panels are transforming the landscape of modern architecture and design. Their unique ridged patterns not only improve visual appeal but also contribute to structural integrity and energy efficiency. With applications ranging from building facades to interior accents, these panels are versatile and practical.

Their durability and low maintenance make them a smart choice for both residential and commercial projects. As the demand for innovative materials grows, fluted metal panels stand out as an attractive option that balances aesthetics with functionality. Embracing this trend can improve design while ensuring long-lasting performance.

Frequently Asked Questions

What are fluted metal panels?

Fluted metal panels are thin sheets of metal featuring distinct ridges or grooves that run vertically or horizontally. These unique patterns enhance visual appeal and provide structural strength, making them popular in architecture and design.

What are the benefits of using fluted metal panels?

Fluted metal panels offer several benefits, including improved aesthetic appeal, structural integrity, and energy efficiency. They enhance visual interest with dynamic light and shadow effects and require minimal maintenance due to their durability and resistance to environmental wear.

Where are fluted metal panels commonly used?

Fluted metal panels are commonly used in various applications, including building facades, industrial cladding, and interior design. They serve both ornamental and protective functions while promoting energy efficiency and reducing noise levels in high-traffic areas.

What materials are fluted metal panels made from?

Fluted metal panels can be made from various materials, including aluminum, steel, and composite materials. Each material offers distinct advantages depending on the intended application, such as weight, corrosion resistance, and durability.

How are fluted metal panels installed?

Proper installation of fluted metal panels involves careful material selection and attention to structural requirements. It’s crucial to provide adequate support, ensure correct spacing to prevent warping, and use appropriate fasteners while considering temperature fluctuations for optimal longevity.